In every vaping device, the atomizer is the assembly containing the heating wire that vaporizes the vape juice. Without an atomizer, you can’t vape – so it’s a pretty important component of your vaping setup. As you look at the history of vaping, you probably pay the most attention to the devices themselves. After all, they’re the products that have shown the most outward changes over the years. We’re here to tell you, though, that the history of e-cigarette atomizers is just as interesting. Just how much has that little heating wire evolved over the years? Let’s dig in.

The Piezoelectric Ultrasound Atomizer

Hon Lik is the Chinese pharmacist credited with inventing the first e-cigarette that reached the commercial market. Hon obtained a number of patents around the world for his invention, and those patents remain valid today. Hon’s first design, however, didn’t use resistance wire to vaporize the e-liquid; it used a piezoelectric atomizer that vaporized the e-liquid with ultrasonic vibrations. The atomizer was, in essence, a tiny speaker that emitted high-frequency sound waves. Hon ultimately decided that he could achieve a more consistent result using an atomizer that vaporized the e-liquid with heat rather than ultrasound. It’s unknown whether any of Hon’s ultrasonic e-cigarettes were ever available commercially.

The USONICIG Rhythm -- pictured above -- was an attempt in 2018 to create a modern vaping device that used an ultrasonic atomizer. It wasn't successful.

Early Resistance Wire Atomizers

The earliest e-cigarettes to reach the commercial market used atomizers based on resistance wire technology, but those atomizers looked very different from today’s atomizers because vape tanks didn’t exist yet.

Early e-cigarette atomizers (left), cartridge (center) and drip tips (right)

The electronic cigarette of the late 2000s and early 2010s was what we now call a “three-piece e-cigarette.” As pictured above, the atomizer was a can-shaped component that screwed into a cigarette- or pen-shaped battery. The atomizer’s heating wire was inside the can, and a steel mesh bridge was at the top of the atomizer. You’d push a plastic cartridge over the atomizer to load your e-cigarette with e-liquid. The atomizer’s steel bridge would compress a wet sponge inside the cartridge, causing e-liquid to flow down to the heating wire.

The sponge-filled cartridges worked well enough to get e-cigarettes off the ground, but they weren’t very reliable. Three-piece e-cigarettes would sometimes stop producing vapor even though the cartridges were still wet. Sometimes, the plastic sponges would overheat and melt. A new technology would soon fix those problems, but in the meantime, the vaping community came up with a solution of their own.

The Vaping Community Invents Dripping and Dipping

Members of the vaping community soon figured out that the early atomizers worked well enough if they were supplied with e-liquid consistently. It was the sponge-filled cartridges that caused the problem of inconsistent e-liquid delivery. To resolve that problem, the community invented dipping and dripping. Dipping became unnecessary as vaping technology advanced, but dripping remains with us today.

Dipping was the practice of putting some e-liquid in a dish and dipping the atomizer’s steel mesh bridge into the dish to supply it with e-liquid. Dipping ensured that the atomizer remained consistently wet, thus making the sponge in the cartridge irrelevant. When the community invented dripping, though, dipping became irrelevant as well.

Dripping involved replacing the e-cigarette cartridge with a hollow mouthpiece – a drip tip – that was placed over the atomizer. You can see some drip tips on the right in the picture above. In this case, you’d supply e-liquid to the atomizer by dripping it directly through the hole at the top of the drip tip. People still drip today, but they now use atomizers specifically designed for dripping.

Cartomizers Make Small E-Cigarettes More Reliable

For e-cigarettes to truly penetrate the mass market, the manufacturers knew that they had to find a way to make the devices more reliable. The technology for that purpose arrived in the form of the cartomizer, so named because it was both a cartridge and an atomizer in a single disposable unit.

Above, you can see a picture of a cartomizer and its interior components. Inside the cartomizer, there was a heating coil with gauze wrapped around it. An air tube isolated the gauze from the cartomizer’s air path and allowed vapor to travel out through the top of the cartomizer. The gauze kept the heating coil wet, and the heat of the coil would continually draw e-liquid toward the center of the cartomizer until the gauze was dry.

The cartomizer worked much better than the original e-cigarette cartridges. Each cartomizer included a new heating coil, and when the cartomizer was dry, the user would throw it away and begin using a new one. Cartomizers are still used for many small e-cigarettes today. At their peak, cartomizers were popular enough that manufacturers made and sold cartomizers that people could fill themselves. That became the genesis of the vaping community’s next great invention.

Cartomizer Tanks Improve E-Liquid Storage

Cartomizers were extremely reliable for e-liquid delivery, but they didn’t store a significant amount of e-liquid; the typical cartomizer held less than 1 ml of juice. The vaping community got around that problem by inventing the cartomizer tank. Someone got the idea that you could drill holes into the side of a cartomizer and enclose the cartomizer in a glass or plastic tank. As you vaped, e-liquid would travel from the tank to the cartomizer through the punched holes, keeping the cartomizer full of e-liquid until the tank was empty. The cartomizer tank made all-day vaping – with no refills – possible for the first time.

The Vaping Community Invents the Rebuildable Atomizer

The vaping community’s last great contribution to the history of e-cigarette atomizers was the rebuildable atomizer. In this case, someone got the idea that the community didn’t need to rely on the manufacturers in China to develop a better atomizer. An atomizer, after all, is just a coil of resistance wire and a wick; people with the appropriate technical know-how could build those themselves.

The rebuildable atomizer sparked a brief boom in which people with the appropriate machining equipment in the United States, Europe and elsewhere were able to build thriving small business by making and selling rebuildable atomizers built from high-end materials like stainless steel and borosilicate glass. You can see one of those early rebuildable atomizers in the picture above.

One of the primary benefits of using a rebuildable atomizer is that, once you’ve purchased the base unit, the parts needed to keep the atomizer going are extremely inexpensive. All that you need are resistance wire and cotton.

Rebuildable atomizers remain an important part of the tapestry of the vaping community today.

The Clearomizer Becomes the First Purpose-Built E-Cigarette Tank

Rebuildable atomizers were great for hobbyists, but mainstream vapers wanted something that was more convenient and easier to use. The manufacturers in China came up with the solution for that problem in the form of the clearomizer. The clearomizer was similar in shape to a cartomizer, but it had a translucent plastic shell – hence the name. Instead of gauze, the clearomizer had a wick that transported e-liquid to the coil – and you could fill it easily just by twisting the clearomizer open.

Clearomizers were essentially the first mass-produced e-cigarette tanks. They’re still in production today, but vape tank technology has advanced so far that few people still use them.

Vape Tanks With Replaceable Atomizers Appear

Most vapers who tried using clearomizers enjoyed them. Clearomizers had a problem, though, in that they were only good for a few uses. Once the tank’s flavor or vapor production began to decline, you’d throw the entire thing away and start using a new one. When a vape tank stops working right, though, the tank itself isn’t the problem – it’s the coil. The tank’s hardware, mouthpiece and outer enclosure are all perfectly good.

The vape product manufacturers in China solved that problem by inventing clearomizers with replaceable atomizer coils. Those were successful for a while, but there was still a problem in that clearomizers were made from plastic. Many people felt that the plastic enclosures changed the flavor of the e-liquid. In addition, some e-liquid flavors – particularly citrus and cinnamon flavors – actually caused clearomizers to crack and break.

Once again, the Chinese manufacturers stepped in and invented something better. That invention was the glass e-cigarette tank with a replaceable atomizer coil. The Kanger Protank – one of the first such tanks – is pictured above. Made from stainless steel and glass, the ProTank delivered a much purer flavor and was a very successful product with the vaping community. Today’s vape tanks still use much the same design.

Sub-Ohm Vape Tanks Push the Envelope of Vapor Production

With the invention of the first glass vape tanks with replaceable atomizer coils, people in the vaping community who weren’t hobbyists – who wanted a great experience, but wanted it to be easy – finally had something that could produce great flavor without an extensive amount of effort.

The only problem: Wouldn’t it be possible to get those things to generate even more vapor?

The vaping manufacturers went back to the drawing board, taking their inspiration from the vaping community yet again. By this time – the mid 2010s – people who used rebuildable atomizers had already begun experimenting with extremely low-resistance sub-ohm coils – coils with a resistance under 1.0 ohm – as a way to vape at higher wattages. All that was necessary was to find a way to fit one of those coils into a replaceable unit that could go inside a glass tank.

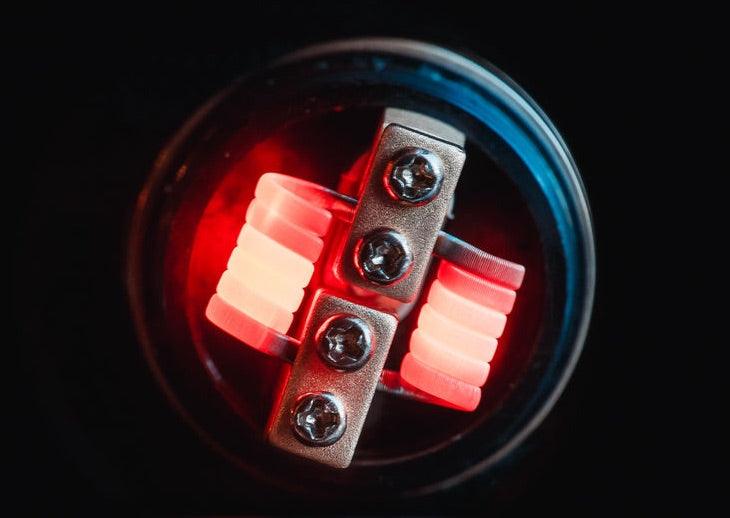

The Kanger SubTank – its coils are pictured above – was one of the first mass-produced sub-ohm tanks. Today, virtually all vape tanks use sub-ohm coils.

Rebuildable Atomizers Come of Age

By the time sub-ohm tanks had found mainstream success within the vaping community, the product manufacturers in China had also taken the rebuildable atomizer paradigm and run with it. That led to the development of new types of rebuildable atomizers – rebuildable dripping atomizers, rebuildable tank atomizers and rebuildable dripping tank atomizers – each with their own sets of features, benefits and drawbacks.

When mass-produced rebuildable atomizers first appeared on the market, they had a major benefit in addition to the benefit of their low recurring costs: they could generate exponentially more vapor than sub-ohm tanks with pre-built coils. Today’s pre-built coils, however, have narrowed the gap and often produce even more vapor than rebuildable coils – so rebuildable atomizers aren’t as popular now as they once were. Narrowing the performance gap, however, required another great technological leap that rewrote the history of e-cigarette atomizers one more time.

Mesh Coil Atomizers Reinvent the Vaping Experience Again

During the second half of the 2010s, each new generation of vape tanks was even more powerful than the generation that came before it. The technological march culminated in the development of tanks like the SMOK TFV12 Cloud Beast King. SMOK TFV12 coils are pictured above. As you can see, the coils for that tank are extremely elaborate. They have up to 12 individual heating wires and require up to 200 watts of power to operate efficiently. The SMOK TFV12 Cloud Beast King certainly did the job when it came to producing extreme vapor clouds, but the tank’s power demands were equally extreme.

Clearly, it was no longer possible to continue increasing the flavor and vapor production of vape tanks with traditional wound heating wires.

The next great development in the history of e-cigarette atomizers came in the form of the mesh coil, an atomizer that replaced the traditional wound wire with a strip of metal mesh. The mesh had the same low resistance and high surface area as a wound coil, but it also had lower mass and could operate efficiently at lower wattages.

The invention of the mesh coil made it possible to get extreme vapor clouds out of a vaping device operating at 100 watts – and sometimes even less – rather than 200 watts. Mesh coils also lasted longer, delivered better flavor and operated without popping, crackling or spitting. Today, virtually all modern vape tanks – such as the new SMOK T-Air – use mesh coils.